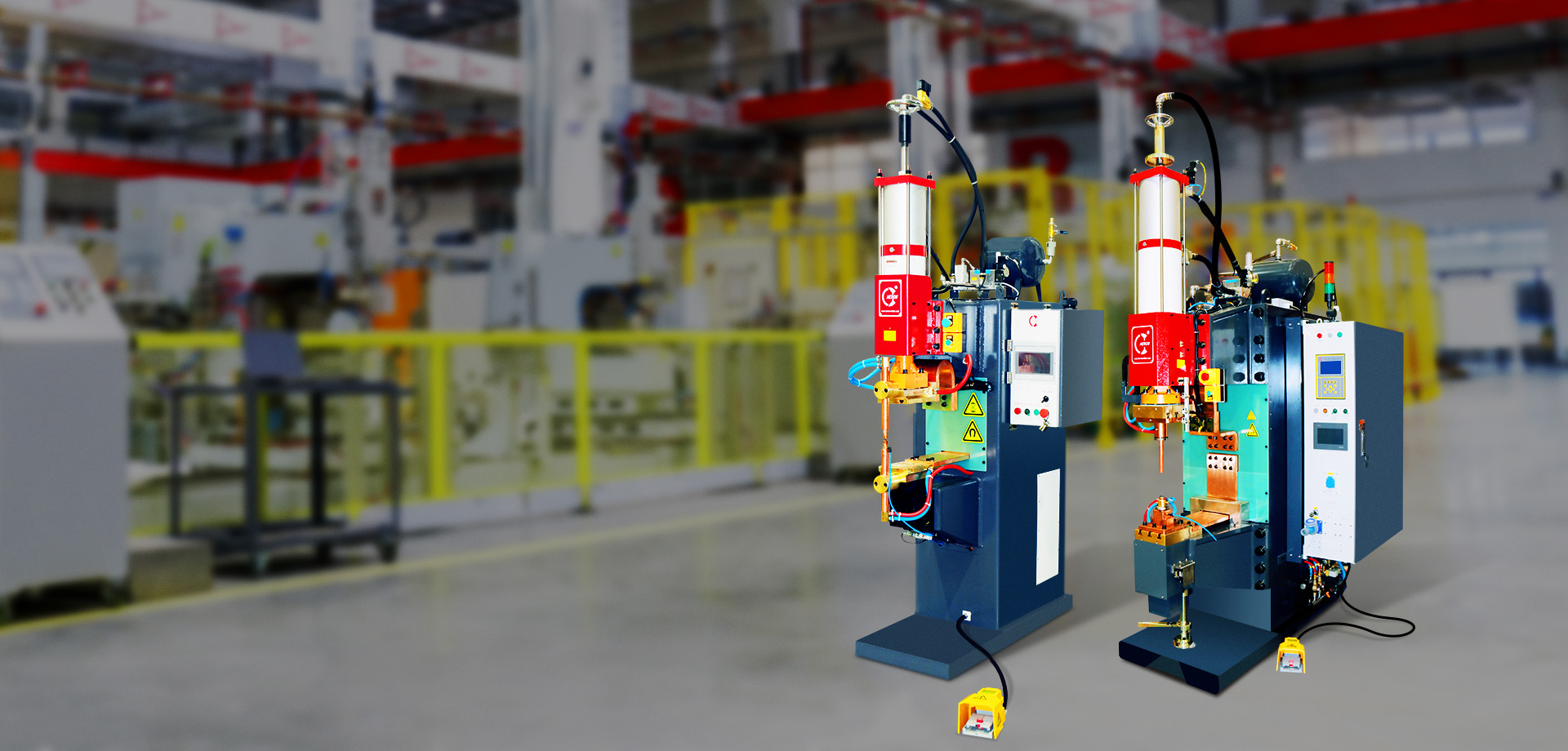

Discover Our Welder Products

With over 30 years of experience, Heron excels in the R&D and manufacturing of high-quality and cost-effective Spot & Projection Welding Machine products and other metal joining technologies. Discover the products we offer.

Heron has a complete series of resistance welding products, including capacitor discharge welding, MFDC, AC, Seam and Butt Welding machines. Our welding product offering ranges from standalone machines to core components such as electrodes, controllers, transformers and weld quality monitors. All of our welders are designed to save energy and promote environmental sustainability while approvedby CCC, CE, ISO9001, CQC.

Advantages of Heron spot welding machines:

- It is widely used in auto parts, home appliance, compressor and general industry etc.

- Modular design, easy to use, service and maintain.

- Delivers superior rigidity, as well as a streamlined standard design.

- Comply with European CE and North American CUL standards.

Looking forward to your inquiry, please leave a message for us, we'll contact you asap

About HERON