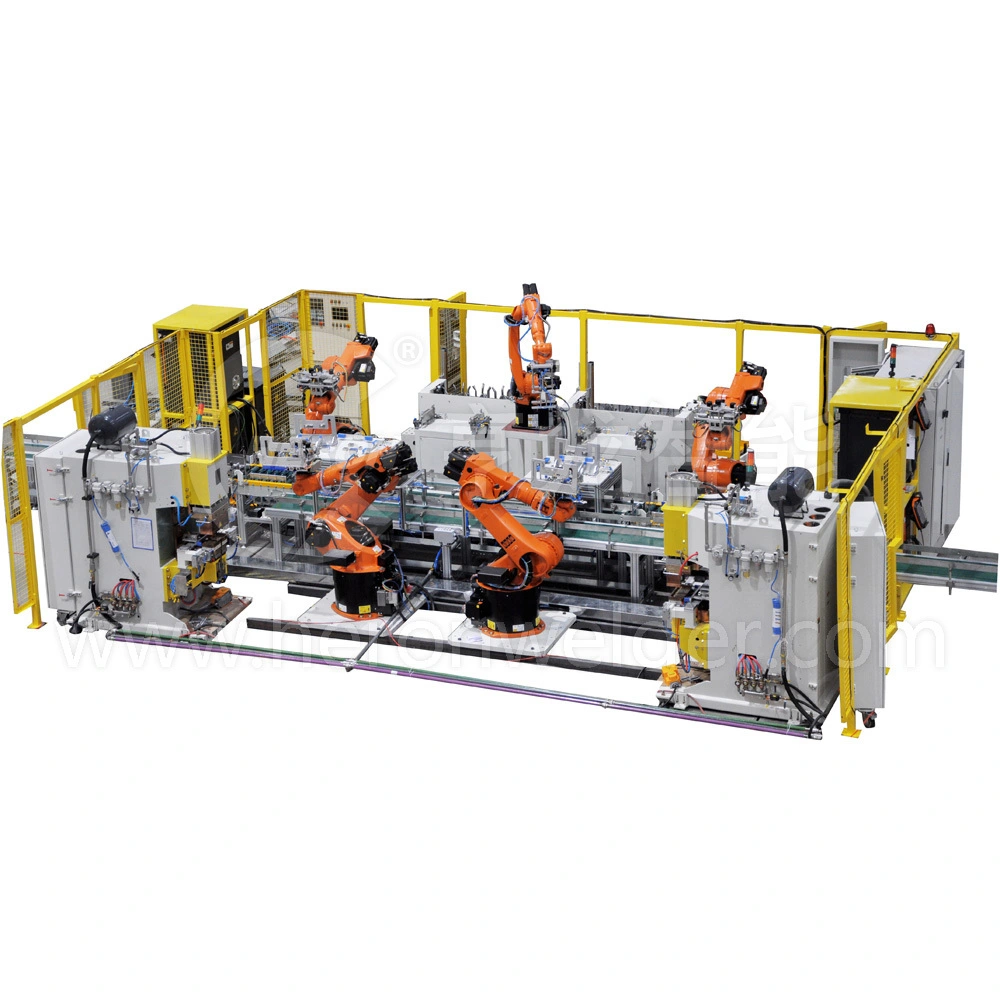

燃气热水器底盖自动生产线

ZA0-F18010

产品功能

1.固定材料盒和自动组装过程的机器人自动抓地力

2. 机器人将自动将组装工件发送到焊接机,以完成焊接

3. 整行只需要由材料补充器维护,不需要操作员

5个ABB机器人,两台15kJ储能焊接机

工作流程:手动材料(上板和下板) - 机器人移植上下板 - 机器人结合底部封面以及上和下板 - 机器人抓取工件焊接 - 成品产品输出

工作节拍:这2台焊接机在这条线上并联,节拍约为10秒/件

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

我们拥有最广泛的生产技术,可实现这些出色的表现和质量。

模型 # | ZA0-F18010 | |

额定容量 | KJ | 20 |

电源 | V/Φ/HZ | 380/3/50 |

Max.Primary 当前的 | A | / |

最大限度。 捷径 当前的 | KA | 102 |

最大工作 压力 | KN | 1.9 |

维度(lxwxh) | 毫米 | 11590x5612x2417 |

亨龙 智能设备铆接设计具有使用的灵活性,耐用性和永恒的需求性。

{{scoreAvg}}

{{item.score}} 星星

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

与我们取得联系

如果您对报价或合作有任何询问,请使用以下查询表。 我们的销售代表将在24小时内与您联系。 感谢你对我们产品感兴趣。

相关产品