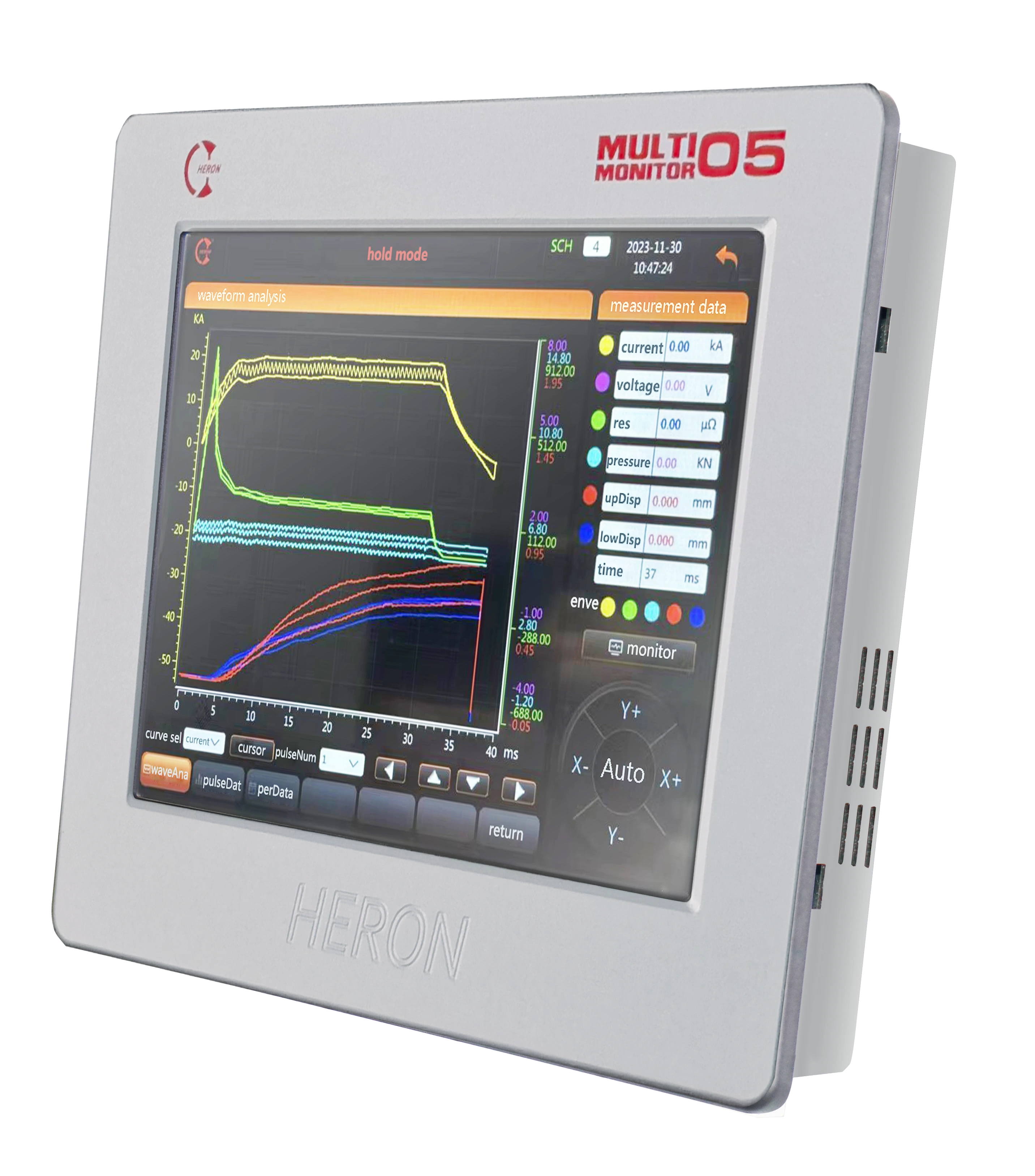

HRC650 resistance welding quality monitor

- It's the industry's first professional device designed to simultaneously monitor 5 key welding parameters. It is capable of real-time monitoring, recording and analyzing almost all important process variables.

- Support for measuring welding equipment such as medium frequency DC, AC (including AC frequency conversion), and capacitor discharge.

- The collected data can be uploaded to the PC, cloud and user MES system through various communication methods such as Ethernet, 4G/5G network and serial port.

- Makes analysis of the welding process simpler and production quality control more convenient. It greatly reduces the impact of frequent inspections on production continuity and quality control costs. Additionally, it can accurately confirm the quality of each welded joint.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Description

An innovative and professional resistance spot /projection welding quality monitor. It's the industry's first professional device designed to simultaneously monitor 5 key welding parameters. It is capable of real-time monitoring, recording and analyzing almost all important process variables.

Application

Suitable for the Capacitor Discharge Welders and the MFDC Welders. Please contact us for specific needs and specification options.

Specification

Welding current range: 6KA, 20KA, 60KA, 200kA, 1000KA; accuracy ±1%

Electrode voltage range: ±20V, ±60V; accuracy ±1%

Electrode pressure range: 2KN,10KN,50KN,200KN;accuracy ±1%

Displacement range:±30mm; accuracy ±0.005mm

Sampling rate:100Khz

Quality monitoring method

Set upper and lower limits/envelope

Trigger mode

Current/pressure

Data traceability

Support the storage of 10 million points of welding data.

Support curve comparison of up to 10 data records.

The built-in 32GSD card can store 30,000 full data files with a sampling rate of 100Khz and one million simplified files with a sampling rate of 1Khz.

File transfer protocol

Modbus tcp/rtu protocol, http protocol, ftp protocol

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

If you have any enquiry about quotation or cooperation, please use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

CONTACT US

Contact Person: Christina Liu

Tel: 86 20 87813325 / 86 20 87819588 / 86 20 87815075

Fax: 86 20 87813346

Address: No.63 Xin Yi Road, Guangzhou, Guangdong China 510990